Empowering Modern Warehouses with Smart Automation

High throughput warehouses require skilled manpower to perform repetitive and mundane tasks. This reduces productivity and subsequently increases operational costs. Shortages in skilled manpower and human errors place significant pressure on businesses, leading to the adoption of a digital workforce and the transition of existing employees to more human-centric roles

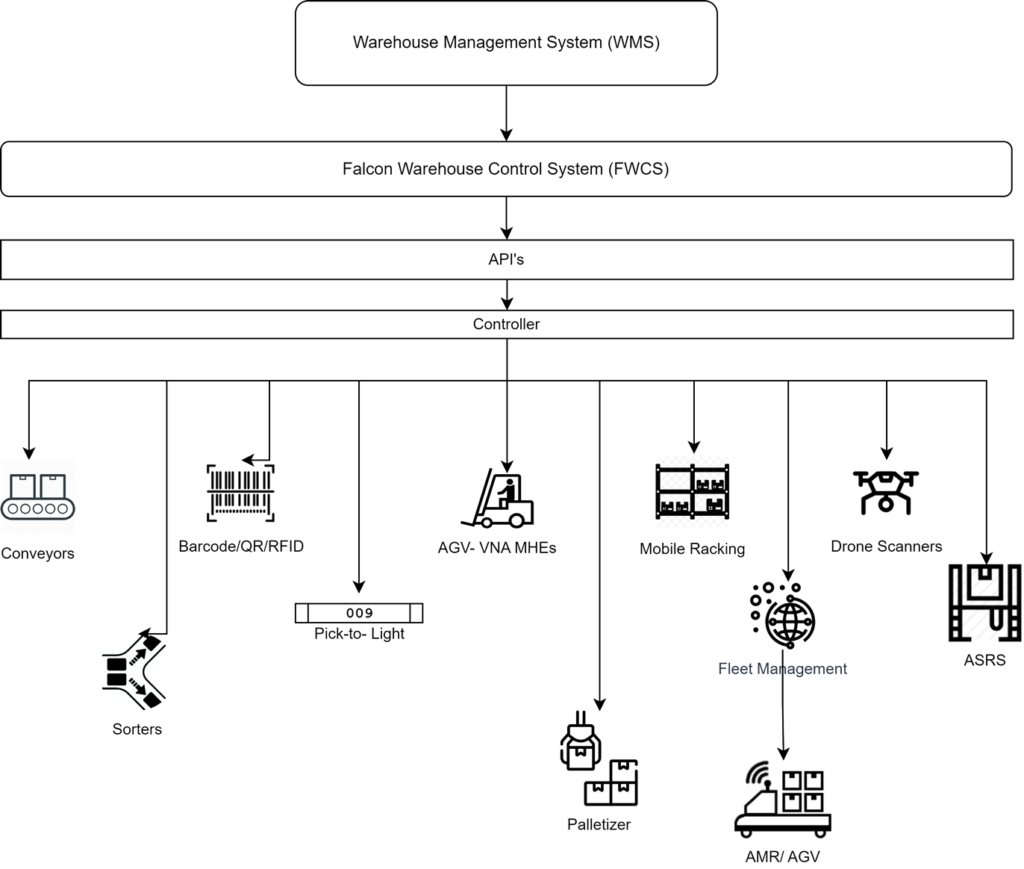

Integrating various automation equipment into different warehouse processes necessitates a collaborative platform to collect, process & control equipment. Falcon Warehouse Control System (FalconWCS) is now focused on serving as an end-to-end collaborative warehouse automation platform for :

Collecting Data from:

- Auto Identity Data Capture devices (Barcode, QRCode, RFID, BLE, Image Sensor)

- PLC, SCADA, OPC/UA sensors on the material flow machines

- Position data from GPS/LIDER/RTLS

- IIoT sensors for condition monitoring devices, dimension scanner, and weight sensors

Processing Data using Decision-Driven Logistics and AI/Machine Learning algorithms.

Controlling Equipment such as: Material Handling Equipment ( AGV/RGV/Conveyor/ Sorters), Pick-to-Light, Voice Picking, Mobile Racking and Autonomous Mobile Robots.

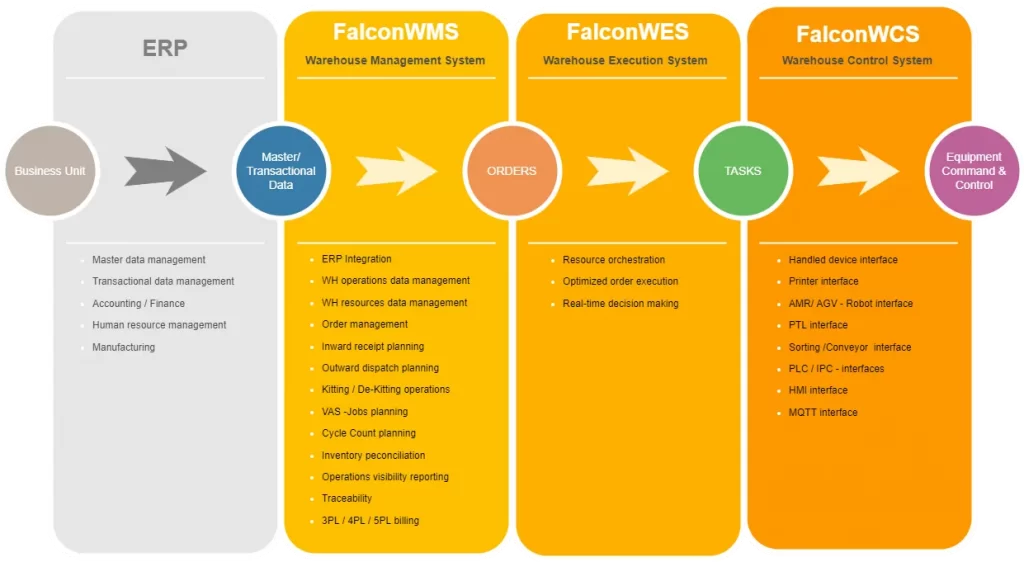

FalconWMS, combined with its native Warehouse Execution System FalconWES and Warehouse Control System FalconWCS, leverages the advantages of warehouse automation in high-throughput warehouse operations

FalconWCS’s job orchestration algorithms ensure optimized task execution with real-time decision-making and a system-driven approach throughout its high-throughput operations.”

FalconWCS makes warehouse automation easy

FalconWCS’s digital workforce orchestration platform support various warehouse automation applications . It ensures full utilization of the equipment with less idle times and work load balancing to perform the jobs in shortest time . System is OEM agnostic and works with MHE equipment that supports industry standard interface. FalconWCS supports following automation:

- Goods-to-Person

- Voice enabled Picking

- Pick-to-Light

- Conveyors & Sorters

- Drone Scanners

- Automated Palletizers & Loading Machines