In today’s fast-moving market environment, businesses cannot rely on intuition or disconnected demand signals to drive cross-functional planning alignment. Demand uncertainty driven by changing customer preferences, promotions, seasonality, and external disruptions often leads to stockouts, excess inventory, and lost revenue.

This is where modern Sales & Operations Planning (S&OP) platforms with integrated intelligent forecasting become a strategic enabler. By combining advanced forecasting engines with cross-functional collaboration workflows, organizations can more accurately predict future demand and align operational plans for optimal performance.

A Unified Platform for Demand Forecasting in S&OP

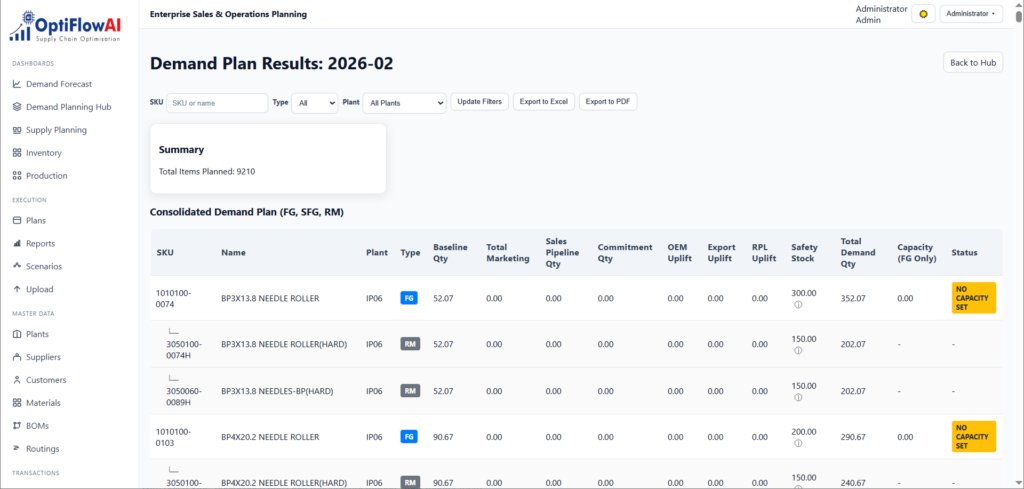

OptiFlowAI, an effective S&OP platform connects demand forecasting with supply planning, inventory management, and executive decision-making. It serves as a central planning hub where data from sales, marketing, and supply chain functions is consolidated into a single, integrated view of future demand and supply capability.

Unlike traditional approaches where departments operate with separate forecasts and tools, a unified platform breaks down planning silos. Real-time dashboards, collaborative workflows, and advanced analytics provide visibility into demand drivers and planning trade-offs, enabling informed decision-making with reduced manual effort.

Key integration capabilities include connectivity with ERP and supply chain management systems, ensuring that planning decisions are always based on the most current operational data.

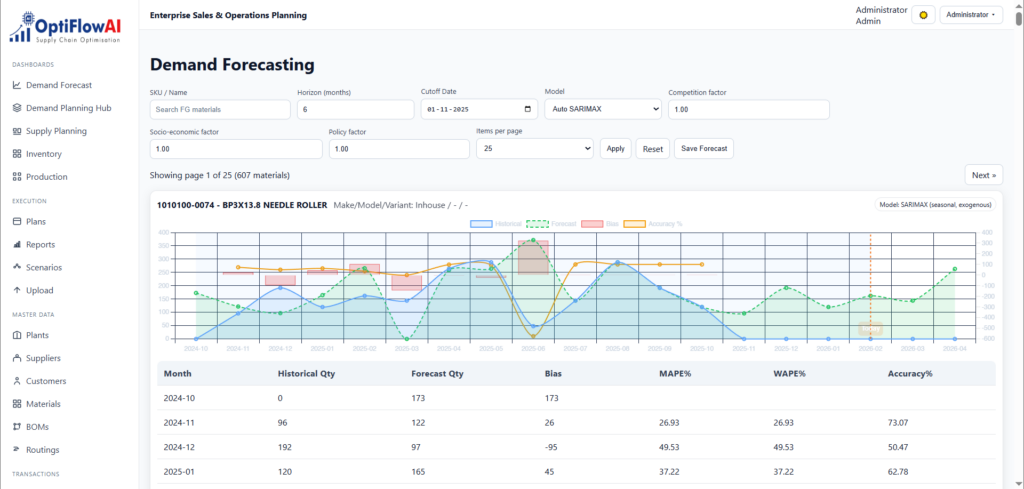

How Demand Forecasting Works Within S&OP

1. Data Collection & Integration

The foundation of effective forecasting is clean, consolidated data. Modern S&OP platforms ingest data from multiple sources to create a comprehensive demand picture:

- Historical sales data: order history, shipment records, and point-of-sale transactions across channels

- Promotions and marketing events: campaign calendars, pricing actions, and historical promotion impact

- Market and external signals: seasonality patterns, economic indicators, and relevant external demand drivers

- Supply constraints and inventory levels: inventory positions, warehouse capacity, supplier lead times, and availability

An intelligent data validation layer automatically identifies anomalies, missing data, and abnormal demand spikes, ensuring forecasts are built on reliable and consistent inputs.

2. Advanced Forecasting Engine

At the core of intelligent demand forecasting lies a multi-model forecasting engine that combines different methodologies to address varying demand patterns:

- Statistical forecasting models: moving averages, exponential smoothing, ARIMA, and SARIMA to capture trends and seasonality

- Machine learning–based models: adaptive models that handle non-linear demand behavior and evolving consumption patterns

- Promotion and event modeling: forecast adjustments based on marketing campaigns, launches, and known demand influencers

This blended approach significantly improves forecast accuracy compared to traditional single-method forecasting techniques.

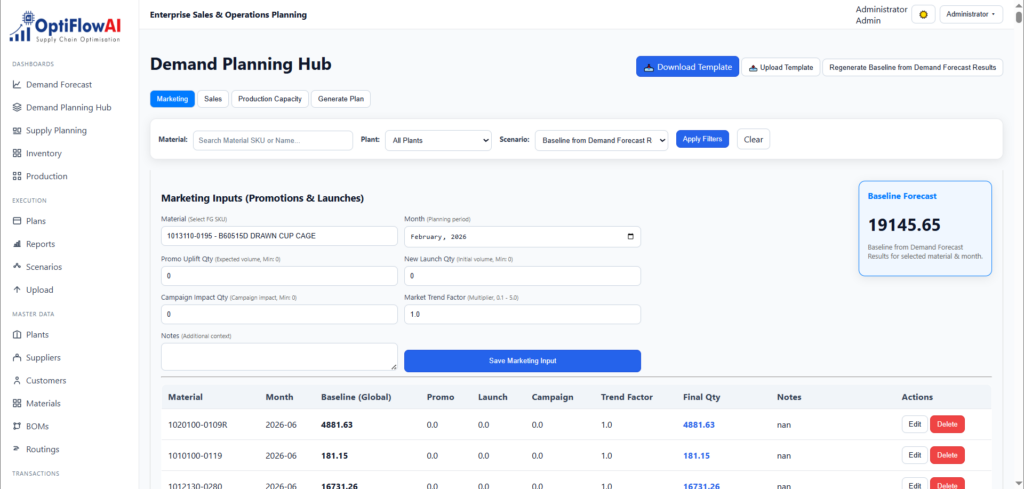

3. Consensus Demand Planning

Forecasts become actionable only when they reflect cross-functional alignment. Built-in workflows and structured review cycles support collaborative demand planning across teams:

- Sales teams review forecasts using market intelligence and pipeline visibility

- Marketing teams incorporate upcoming campaigns and expected demand impact

- Operations teams evaluate feasibility, capacity constraints, and supply risks

Exception-based reviews, approval workflows, and version control help align all stakeholders around a single, agreed-upon demand plan.

4. Scenario Modeling & What-If Analysis

Effective demand planning requires preparation for uncertainty. Scenario modeling capabilities allow planners to evaluate alternative business situations, including:

- Demand surges driven by promotions or market shifts

- Supply delays, capacity constraints, or operational disruptions

- Expansion into new markets, regions, or channels

Scenarios can be compared side-by-side using key operational and financial metrics, enabling proactive decision-making rather than reactive firefighting.

Key Business Benefits

- Reduced Stockouts and Excess Inventory

Improved forecast accuracy helps align inventory levels with actual demand while minimizing carrying costs. - Improved Supply Chain Planning and Execution

Reliable demand signals enable better coordination across procurement, production, and distribution. - Stronger Cross-Functional Alignment

A shared demand plan reduces conflicting assumptions and accelerates decision-making across functions. - Better Financial Planning and Forecast Visibility

Demand forecasts directly support revenue planning, budgeting, and early identification of risks and opportunities. - Increased Agility and Faster Decision-Making

Scenario-based planning enables organizations to respond quickly to demand shifts and disruptions.

Conclusion

Demand forecasting delivers the greatest value when it is collaborative, data-driven, and tightly integrated with the S&OP process. By combining advanced forecasting models, cross-functional workflows, and scenario analysis within a unified planning framework, organizations can move from reactive planning to proactive decision-making.

The result is a more resilient, agile, and well-coordinated planning process—one that enables organizations to meet future demand with clarity and control.